Polpharma API CDMO (Contract Development and Manufacturing Organization) supports emerging and large pharmaceutical customers in the development and commercialization of their small-molecule APIs clinical candidates to market. With over 70 years of experience, we provide process development, scale-up and cGMP manufacturing of small-molecule APIs in varying volumes from kilos to tens of tons.

Polpharma is one of the top CDMO companies producing APIs in Europe. We engage with our clients’ projects from early-stage clinical candidates to commercial launches throughout the product life cycle. Our state-of-the-art facilities in R&D, pilot, manufacturing, and QC, coupled with our extensive experience in developing and manufacturing highly complex active pharmaceutical ingredients, enable us to provide our clients with a wide range of services across the value chain.

R&D laboratories

Among crucial technologies, expertise, and CDMO services that we can provide to our partners there are R&D laboratories

- Process chemistry, from full development, through transfer, to production

- Analytical methods transfer, development, validation

- Process development, process optimization

- Second-generation process for cost control

- FDA-approved GMP facilities from pilot plant scale to multi-ton manufacturing scale.

- Security of supply assured by network of well-established partners or back integration of intermediates and starting materials.

- State-of-the-art QC laboratories for product release.

- Dedicated Project management to ensure the best possible customer experience.

Strong R&D management team with a great experience in the development of chemical

processes and complex projects, provide a wide range of solutions to our customers.

Our R&D team is equipped with about 1 000 sqm facility counting 10 laboratories,

30 fume hoods with state-of-the-art instruments to support chemical and analytical development projects.

- New chemical routes full development

- Process optimization

- Technical transfer

- Analytical methods development, transfer, validation

- Troubleshooting

- Crystallization studies

- Particle size distribution control

Polpharma API CDMO is experienced in developing and manufacturing processes using a variety of chemical reactions and conditions, including cryogenic, high pressure, strong bases reactions, API micronization, injectable grade APIs.

Key technologies & expertise

- Amidation

- Alcylation

- Acetylation

- Bromination

- Chlorination

- Chlorosulphonation

- Cyclization

- Coupling

- Carboxylation

- Dehydrogenation

- Lithiation (with BuLi)

- Esterefication

- Friedl- Craft’s alcylation

- Grignard’s reaction

- Hydrogenation

- Methylation

- Metho-/ Ethoxylation

- Oxidation/ Reduction

- Phosegenation (with triphosgene)

- Saponification

- Strong base reactions

Pilot Plant

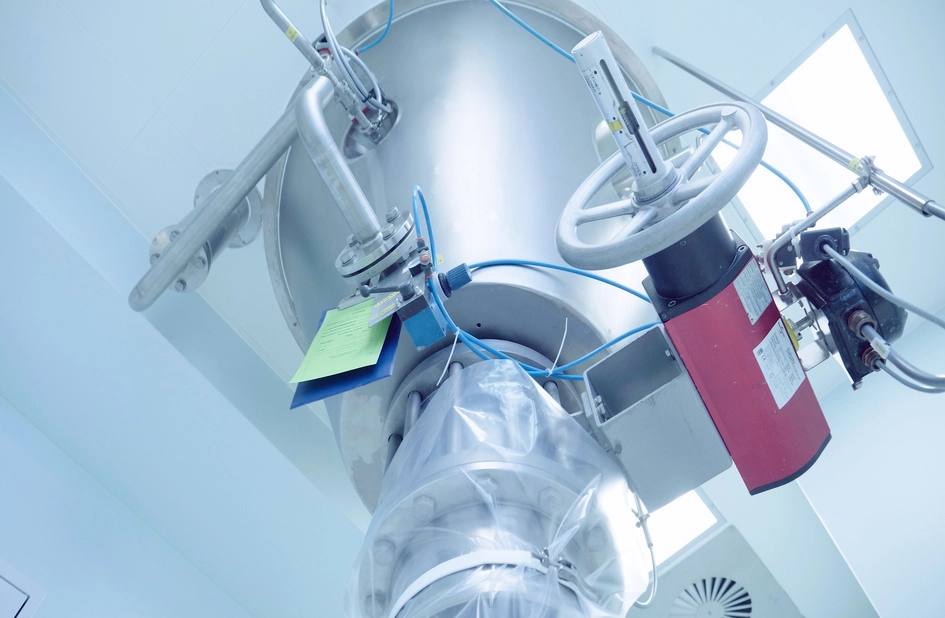

Our Pilot Plant is an independent, small scale FDA approved production facility counting more than 25 reactors and vessels from 50 to 650 L for a total of 6 m3 capacity.

3 different and fully segregated clean zones for final APIs processing enable 3 parallel projects to run independently. Pilot Plant operations are designed and maintained an exactly the same standard as the production environment at the target commercial scale, which ensures a smooth process transfer at a larger scale (same quality, EHS standards, format for Batch records and SOP’s are applied as for production areas).

This facility runs 24h/day and 7 days/week and giving its capacity and flexibility is used for both scale-up studies to prove process robustness and also routine manufacturing of relatively small volume commercial API.

Dissolutors: 500 dm3 SS, 250 dm3 GL and 100 dm3 GL

Security of supply

While working on your Drug Substance, we will take care of the entire supply chain for all the materials required to secure on-time production and delivery.

- Paper Audit.

- Personal on-site Audit (For Intermediates and selected Regulatory Starting Materials).

- Risk-based approach.

- Managed by a separate QA Team dedicated to Suppliers Qualifications.

- Own a Team of well-trained auditors. Auditors employed by Polpharma have a seat in Asia.

- Periodic requalification (Every 3 years).

A broad network of reliable European suppliers qualified for solvents and basic chemicals that are in common use in API production.

Wide group of high-quality, GMP-compliant suppliers for Intermediates and Starting Materials qualified by Polpharma ready to produce custom intermediates on an exclusive basis.

Multipurpose lines give flexibility in planning and enable to implement your process in different lines as a contingency plan.

Experienced Regulatory affairs group supporting clients in CMC package preparation for filing.